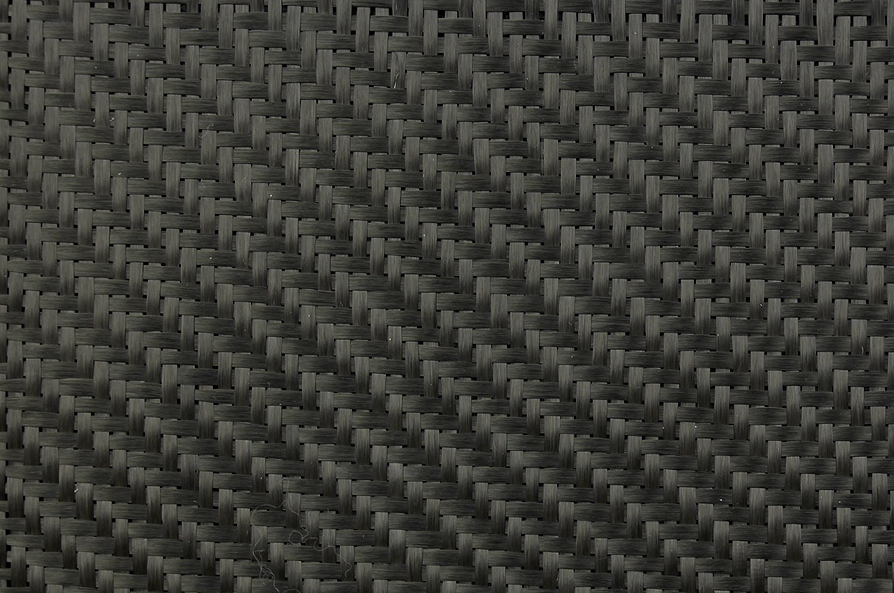

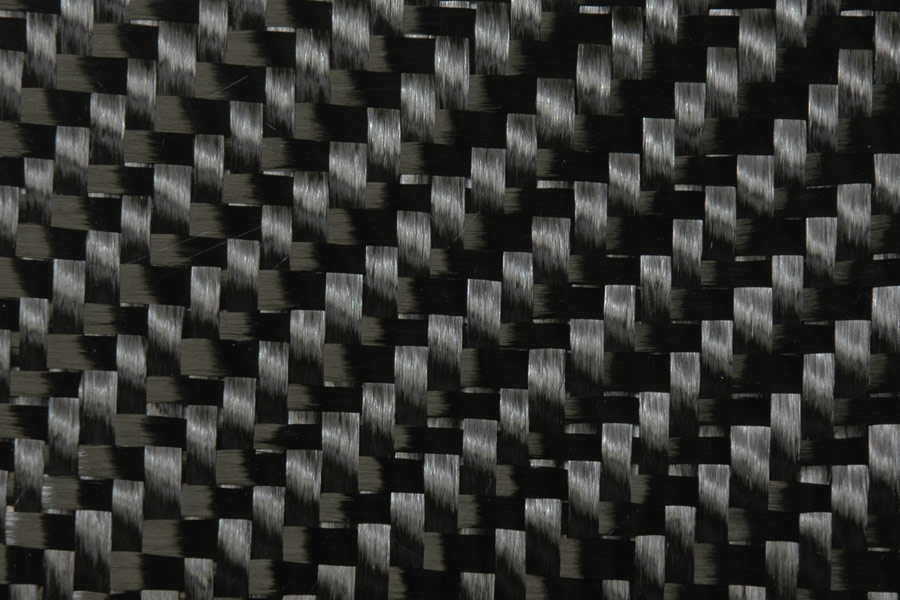

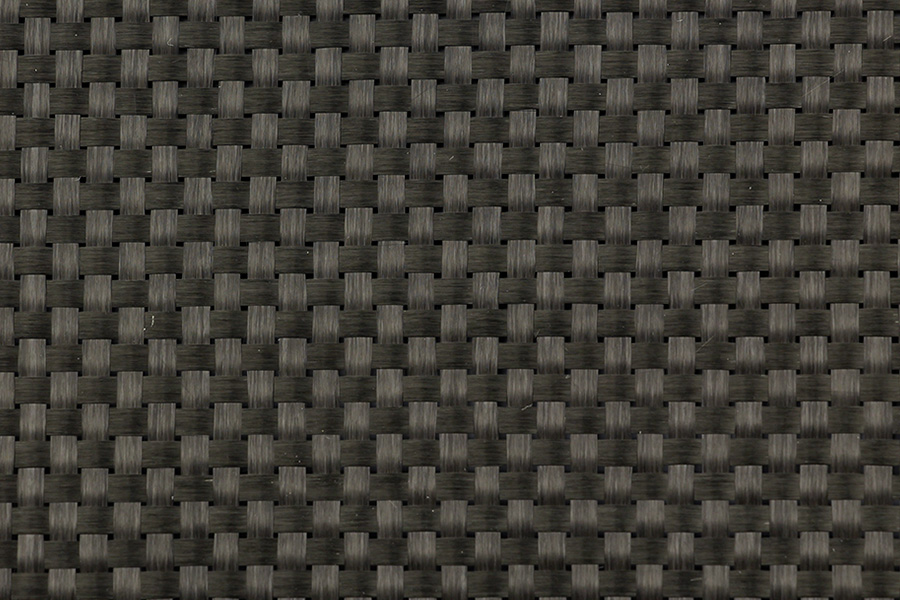

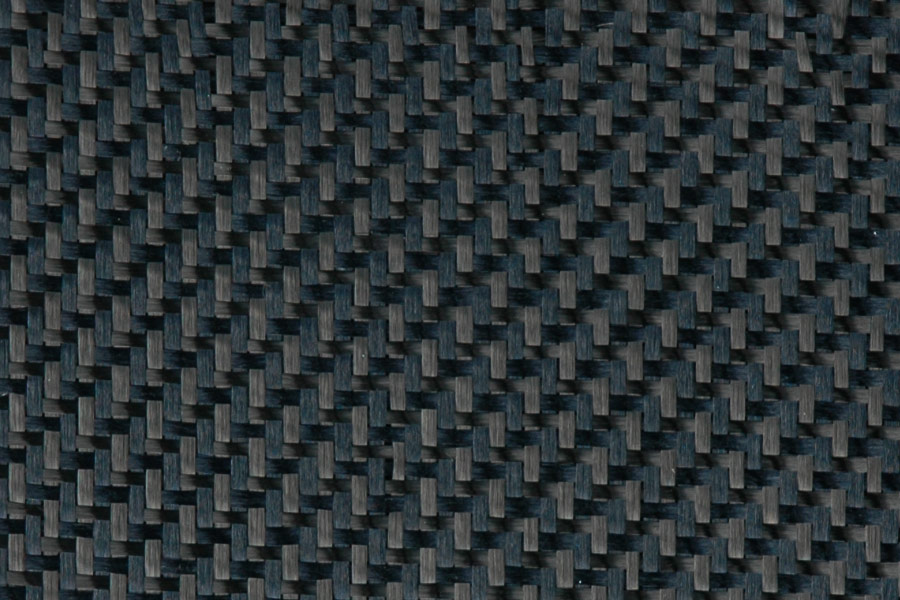

We use high quality raw materials. Benefits of this fabric are low weight and high strenght. The final design of the product depends on the type of fabric's weave which also influences the physical features of the product. We use following types of carbon fabrics:

Carbon-twill

Carbon-Twill-Wide

Carbon-Plain

TeXtreme

Aramid fabric provides heat and flame resistance and impact destruction resistance (often used in motorsport because of regulatory requirements). We use following types of aramid fabrics:

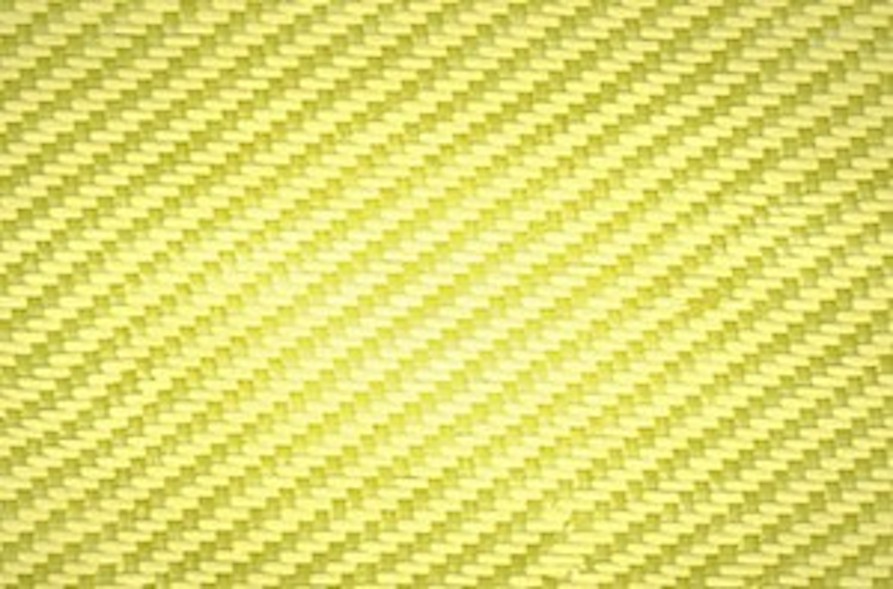

Twill

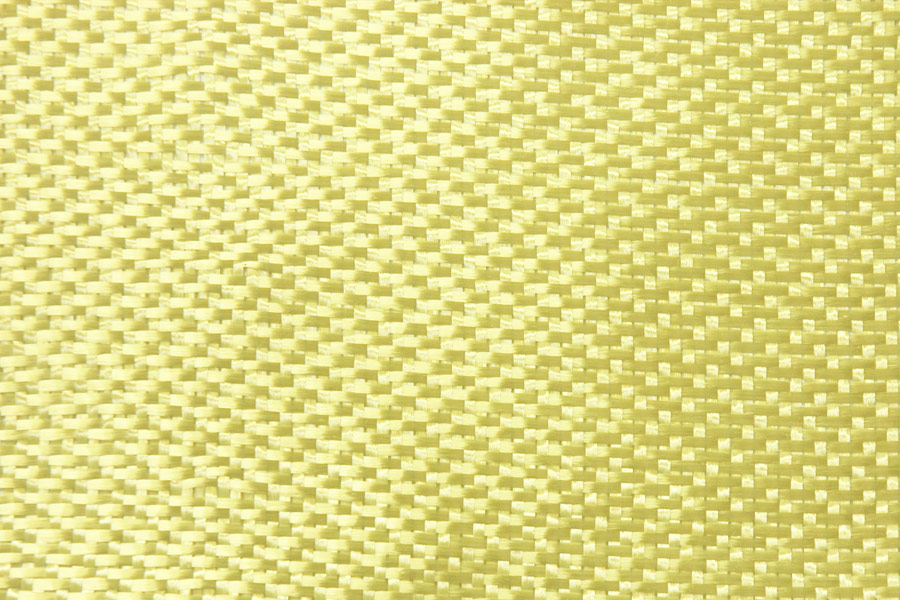

Plain

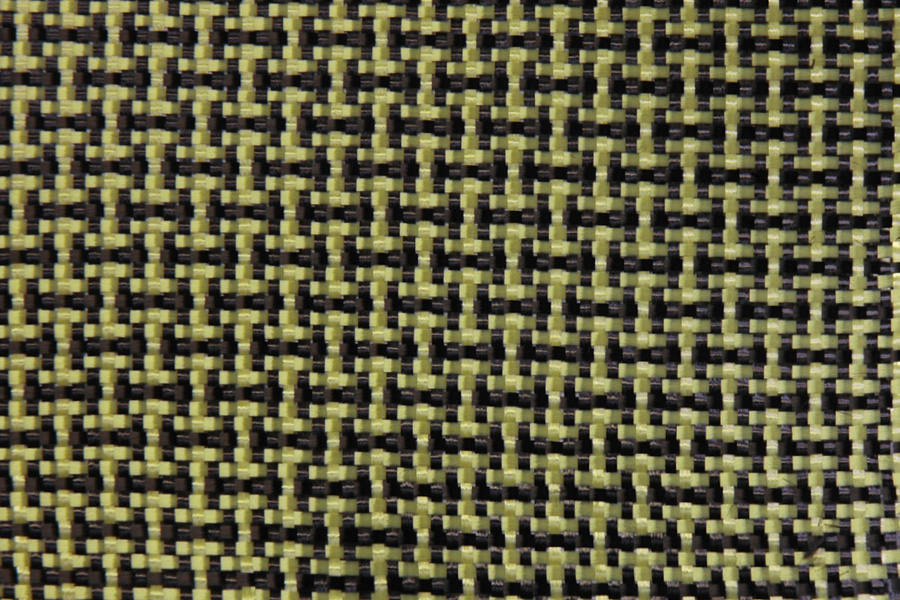

Combines benefits of both fabrics - the stiffness and strenght of carbon and the abrasion, fracture or impact resistance of kevlar. The fibre is suitable for challenging conditions. We use following types of fabrics:

Twill

Plain

Twill

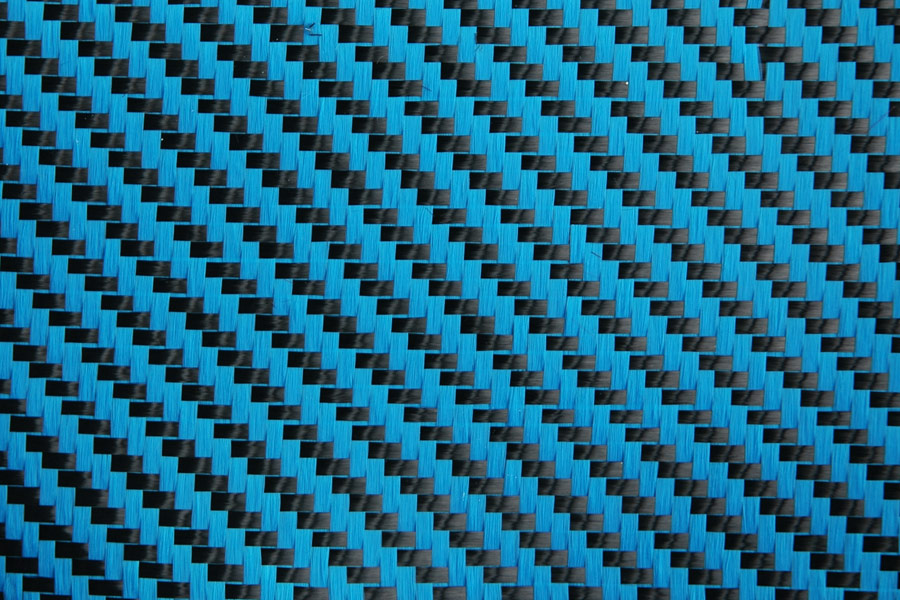

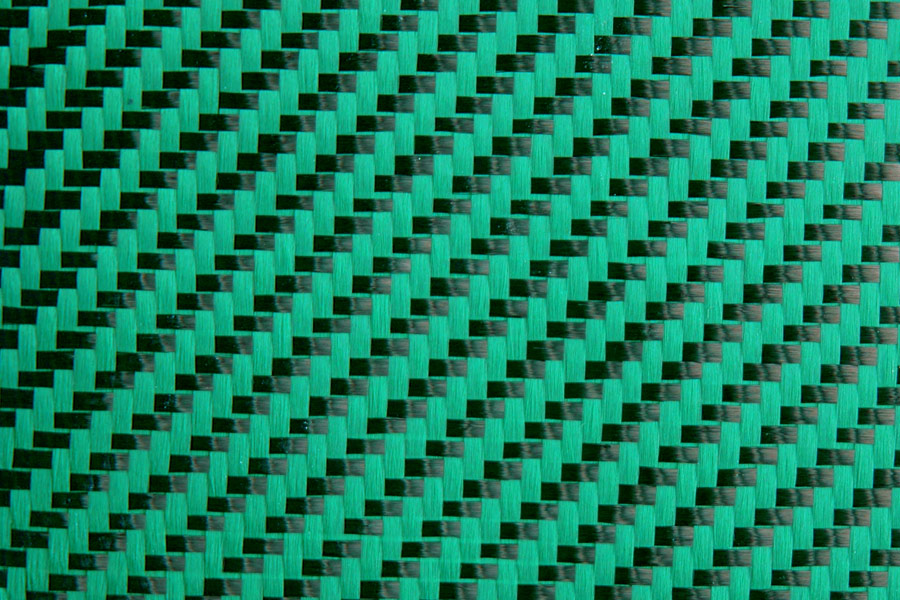

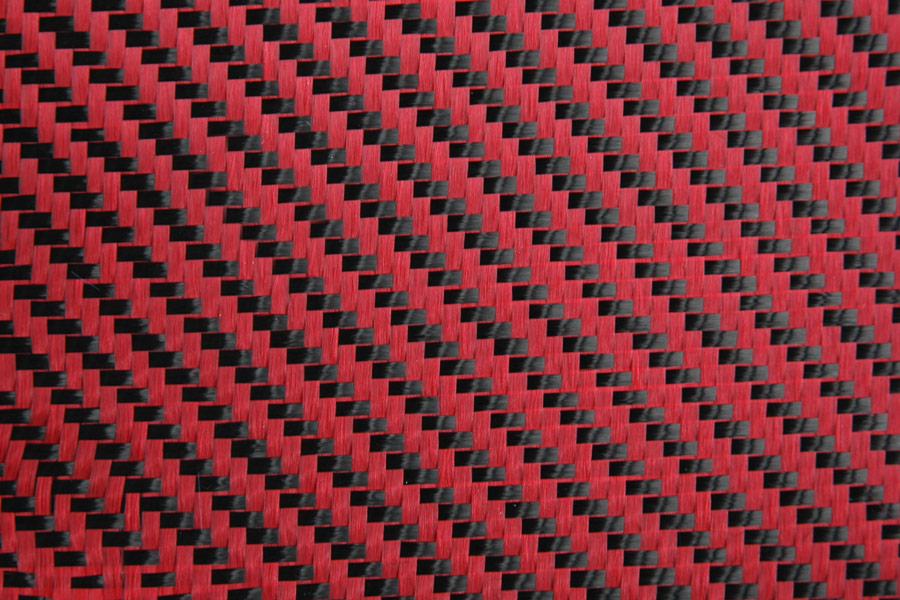

This special coloured fabric is made from carbon fiber and coloured polyester fiber. Thanks to the colour your part can have unique design. We use 2/2 twill fabric in 3 colours:

Blue Carbon

Green Carbon

Red Carbon

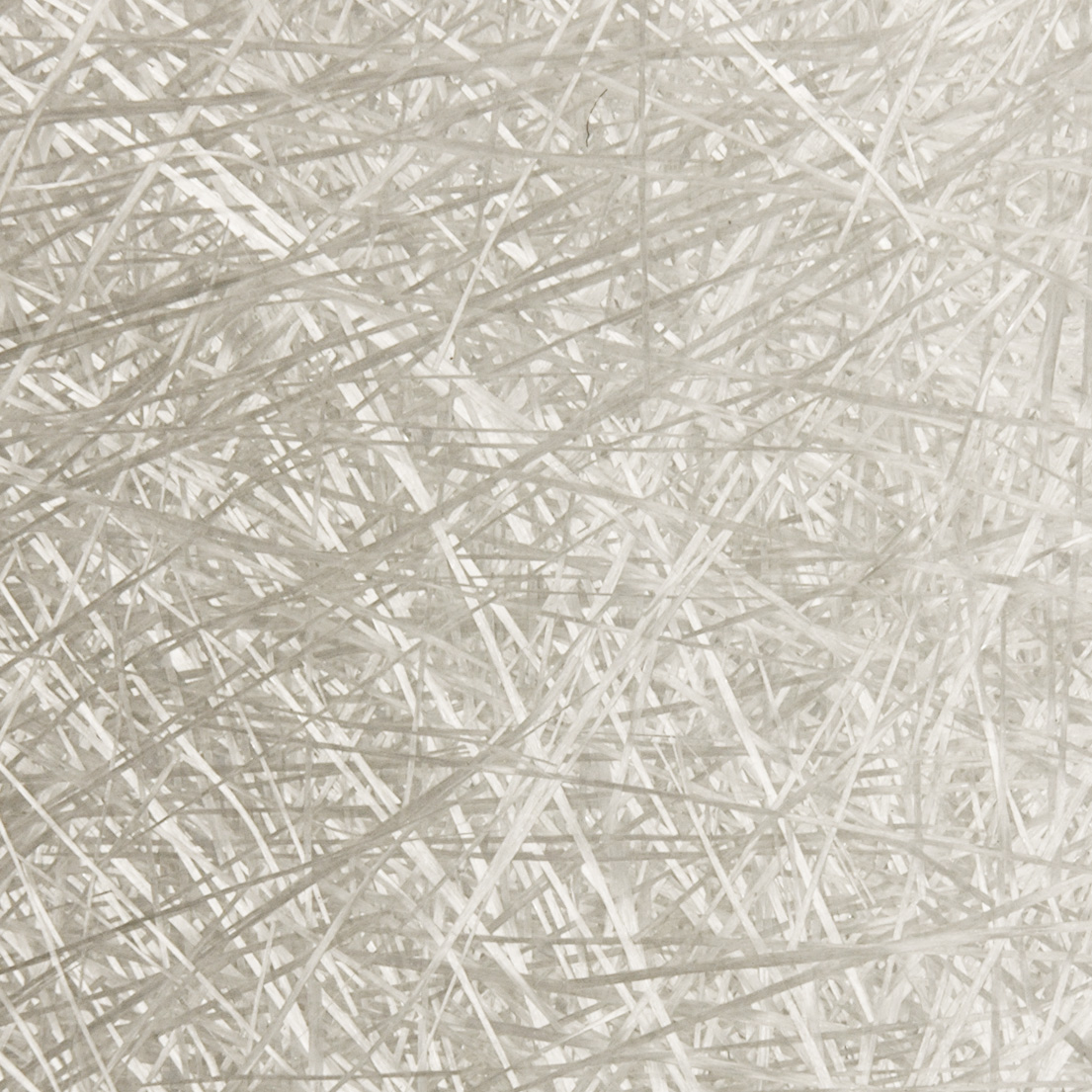

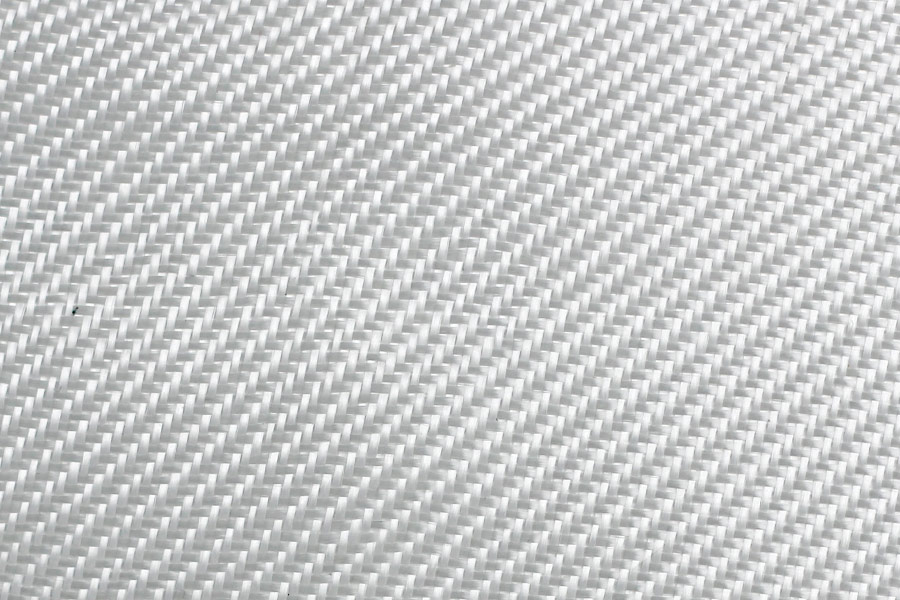

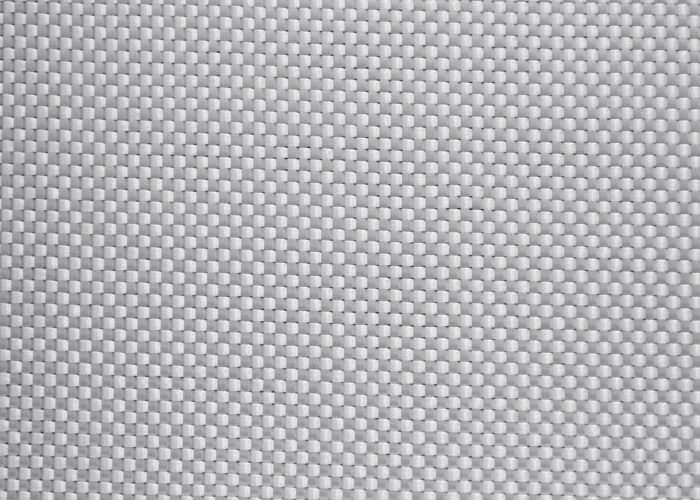

Widely used reinforcing fabric. Glass fabric is fire/chemicals resistant, but it has low resistance to the longterm straining and abrasion. We use the following fabric's weaves:

Twill

Plain

Chopped Strand Mat (CSM)